Offshore

Our team of offshore experienced civil engineers offers you the following services.

Our references include wind farms on the North Sea and Baltic Sea as well as on the Atlantic.

We also have all the necessary offshore certificates including HUET.

Core samples from grouted joints

In order to assess the condition, load-bearing capacity and durability of the grout connection of a wind turbine, it is necessary to take concrete samples in the form of core samples from the grouted joint.

- Grout sampling via core drilling (vertical or horizontal)

- Non-destructive attachment of the drilling equipment

- Camera inspection of the drill holes

- Filling the drill holes with grout material

- Transport of the concrete samples to any testing institute

You can download our flyer on drill core taking from grout joints here:

Steel samples

- Taking steel samples, for example to assess the condition of the shear keys

Water pressure tests

If cavities within the grout connection are suspected, for example due to cracks in the drill cores or water leaks from the grout connection, then the water pressure test is a suitable method for determining the permeability of the concrete structure. To do this, the steel of the pin and the grout material are drilled through in several places and sealed with packers. These are then pressurized one after the other with water at a defined pressure. The amount of water absorbed per unit of time is recorded based on the injection pressure.

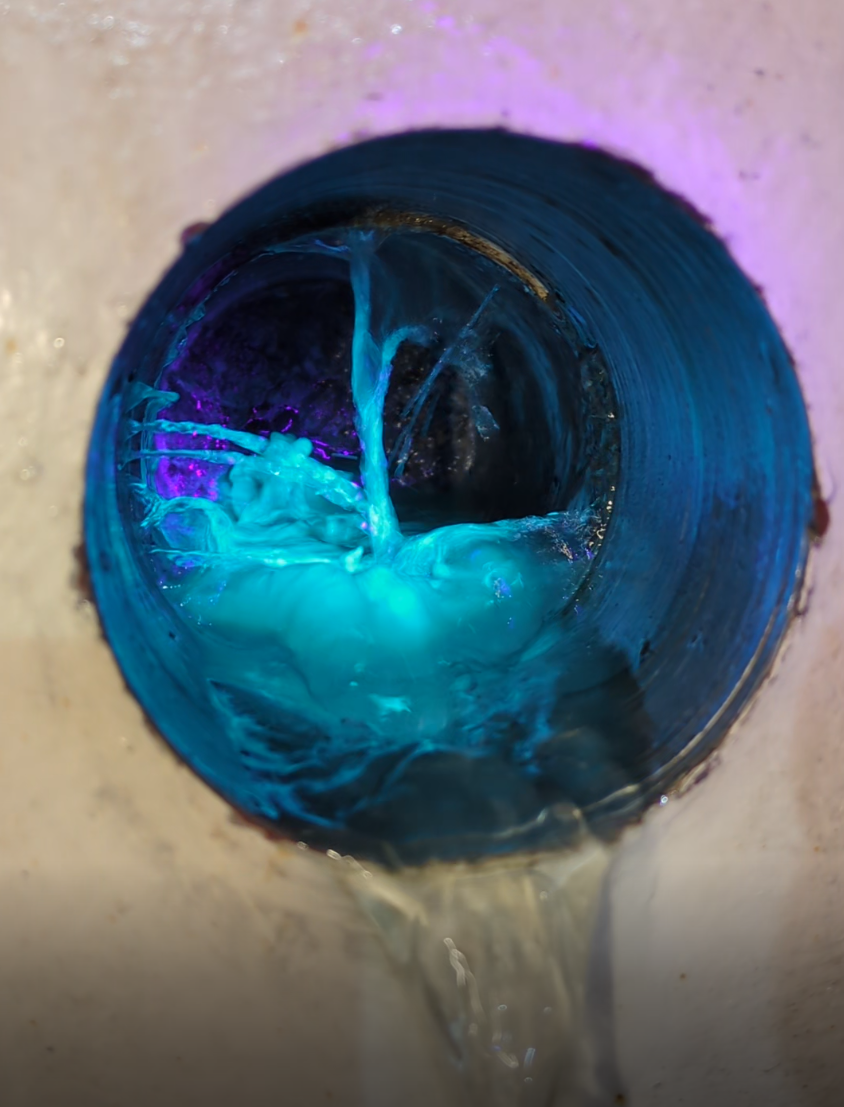

The test results provide information about the permeability of the concrete structure. In addition, the bond between the steel walls and the grout can be examined. As can be seen in the pictures below, when a packer was applied, water escaped between the steel wall of the pin and the grout, which means that the material bond is no longer complete.

Regrouting: Injection of cement suspension

To repair grouted joints, we've already successfully used the method of injection.

In order to close cavities within the grout or to restore the bond between the steel walls and the grout, it is advisable to inject a cement suspension based on ultra-fine hydraulic binder. For this purpose, the permeability of the concrete structure is initially determined using water pressure tests. The packers that were used for the water pressure tests can then be used for injection with cement suspension. The advantage of cement suspension over injection resins is, among other things, the possibility that moist and water-bearing cavities can be filled in a force-fitting and form-fitting manner.

Subsequent sealing of the annular gap below the grout seal

We also offer subsequent sealing of the annular gap below the grout seal. This permanently elastic seal with a seawater-resistant elastomer hose, which is pressed on with mortar, was specially developed and protected by patent.